Advanced Synergy: Optimizing Indoor Climate and Lighting with CO2

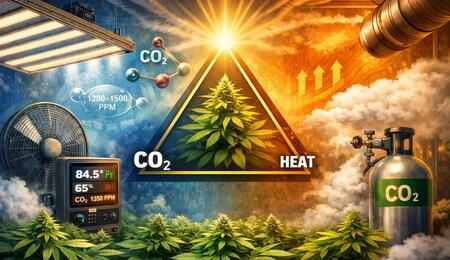

To achieve professional-grade yields in 2026, growers can no longer rely solely on buying the strongest light or the largest fan. Optimal cultivation relies on the “Golden Triangle”: the biological relationship between light intensity, carbon dioxide (CO₂) levels, and temperature. When these three factors are synchronized, you unlock a metabolic “overdrive” in the cannabis plant. However, if one factor is out of balance, the entire system can become physiologically harmful to the plant. This guide explores how specific advanced products can be used to master that synergy.

The Biological Limit: Why CO₂ is the ‘Missing Link’

In a standard grow room, CO₂ levels hover around 400 ppm (parts per million). At this level, a plant can only process so much light. Running a high-performance LED at full output without added CO₂ limits the plant’s ability to use the extra energy. This leads to light stress, bleached buds, and stunted growth.

By introducing CO₂ enrichment (aiming for 1,200–1,500 ppm), the plant’s “saturation point” is raised, allowing it to absorb more light and thrive under higher temperatures.

Phase 1: High-Intensity Lighting Integration

Lighting Optimization: To trigger the benefits of CO₂, growers must provide a saturating level of light, measured as PPFD (Photosynthetic Photon Flux Density). For advanced operations, this means reaching levels of 1,200 to 1,500 µmol/m²/s. Certain high-output LED fixtures are capable of delivering full-spectrum “white” light for deep canopy penetration, helping lower bud sites receive adequate energy for photosynthesis. Growers may choose from a variety of commercial LED options that meet these intensity requirements.

Climate Optimization: The primary challenge of high-intensity lighting is radiant heat. Even though modern LEDs are more efficient than old HPS bulbs, they still emit significant heat from the diodes. In an optimized CO₂ environment, you actually want the room to be warmer (between 82°F and 85°F), but this heat must be kept uniform. Proper oscillating air movement helps break up microclimates and heat pockets that form directly under high-intensity LEDs, preventing leaf burn while keeping the metabolic rate high.

Phase 2: Mastering VPD (Vapor Pressure Deficit)

Climate Optimization: VPD is the measurement of how much “room” the air has for more moisture, which dictates how fast plants “breathe” or transpire. In a high-heat, high-CO₂ room, maintaining a VPD of 1.2 to 1.5 kPa during flowering is critical. To manage this, reliable environmental sensors are essential. Some growers have good experiences with smart sensors such as Pulse Pro, while others use Sensor Push or similar brands. These sensors are valuable for detecting when humidity is too low. If the air is too dry at 85°F, the plant will close its stomata to save water, severely limiting its ability to take in CO₂.

Lighting Optimization: The lighting schedule must be perfectly timed with the climate shifts. TrolMaster, AC Infinity, Growflux and Vivosun are among the most popular controller choices among growers. As lights ramp up in intensity, the plant’s demand for water increases. If light intensity is at its peak but the climate is out of range, the plant will suffer from transpiration stress. The light dimming curve should always match the dehumidifier’s ability to keep up with the increased moisture the plants will be releasing into the air.

Phase 3: CO₂ Enrichment Products & Implementation

Climate Optimization: Adding CO₂ changes the exhaust strategy. When a traditional “always-on” exhaust fan is used, much of the added CO₂ is simply pulled out of the space. This can be improved by switching to a closed-loop system or a timed exhaust approach. CO₂ bags are supplemental rather than precision tools and are best suited for small tents. In larger or professional setups, growers often use tank-based CO₂ systems paired with reliable regulators—options from manufacturers such as Titan Controls or Autopilot are commonly used. These systems should be linked to an environment controller that shuts off the CO₂ when the exhaust fan is active.

Lighting Optimization: When the CO₂ is flowing, cannabis plants can handle “Overdrive” lighting. This is the time to utilize the “Boost” setting on LED drivers. Because the CO₂ allows the plant to stay healthy at higher temperatures, the lights can be positioned slightly closer to the canopy than in a “non-CO₂” setting. This can significantly increase light density (PPFD), promoting more robust bud development and improved structural integrity. However, growers must not forget that it is also important to monitor canopy temperature by utilizing IR thermometers or leaf temp sensors (ideal leaf surface temperatures typically fall between 78–82°F in CO₂-enriched rooms).

Phase 4: Fueling the Fire—Soil Amendments and Boosters

Climate Optimization (Nutrient Uptake): As temperatures rise to the 85°F range to accommodate CO₂ enrichment, the rate of evaporation from your growing medium increases. This can lead to a “salt buildup” if you are using standard bottled nutrients. To mitigate this, advanced growers should consider Organic Living Soil amended with high-quality Biochar or Rice Hulls. These amendments act as a root-zone buffer, retaining moisture and beneficial microbes that protect the roots from the higher ambient heat required for the CO₂ strategy.

Lighting Optimization (Metabolic Demand): When pushing 1,500 PPFD, the plant’s demand for calcium (Ca) and magnesium (Mg) can increase. Under these lighting conditions, growers may use a Cal-Mg booster or an organic equivalent such as Coconut Water Powder, which provide cytokinins, potassium, and enzymes. Adding a silica supplement can support stronger cell walls, helping the plant maintain structural integrity under CO₂-enriched conditions and tolerate higher canopy temperatures. Growers typically source these supplements from established nutrient manufacturers such as CANNA, whose nutrient research is globally referenced in professional cultivation circles, Advanced Nutrients, or Botanicare, with preferences varying by formulation style and feeding approach.

Summary: The Synergy of Hardware

Climate Focus: Success in 2026 relies on automation, especially when it comes down to more professional or advanced grow setups. An integrated environmental controller can coordinate fans, humidifiers, and CO₂ injectors to work together, preventing the “seesaw” effect in which devices counteract each other, wasting energy and stressing the plants. Many growers use commercial systems such as AC Infinity UIS or Autopilot for this purpose.

Lighting & Soil Focus: Never forget that light is the fuel, but the soil is the engine’s cooling and delivery system. Using high-output LEDs alongside CO₂ can increase the plant’s metabolic activity. This should be supported by a robust, silica-rich soil structure and a “Living Soil” approach to protect the root zone under higher ambient temperatures. When these elements are properly aligned, they can enhance secondary metabolite production and overall plant quality.

Warning: Horticultural CO₂ enrichment should only be used in well-ventilated areas with a CO₂ safety monitor, as high levels of carbon dioxide can be hazardous to human health. This guide is for educational purposes for legal cultivators; always comply with your local state and federal regulations regarding cannabis cultivation.

More from Soft Secrets: