The Science of Carbon Filtering

Carbon filters are one of the most vital components of any indoor cannabis operation, improving air quality and acting as the primary line of defense against unwanted odors. They are commonly used to remove the smell of marijuana in grow rooms, especially in places where the ventilation of air is poor. The filter uses activated carbon to eliminate smell particles and other impurities invisible to the human eye but that can be present in the air.

For growers seeking 100% odor mitigation, understanding the core science behind carbon filtering—specifically the process of adsorption—is key to purchasing and maintaining the right system.

Adsorption vs. Absorption: Understanding the Key Difference

The process that makes carbon filters work is often confused with a similar term. Adsorption is only one letter different from absorption, and it’s an entirely different physical/chemical process.

- Adsorption: When a substance adsorbs something, it basically attaches to it. Adsorption is the quality of a solid compound to attract and trap gas, liquid, or dissolved solid molecules to its surface. As liquid or air comes into contact with active charcoal, intermolecular forces draw molecules into the millions of pores dotting the carbon surface. The carbon particle acts as a magnet, holding the contaminants on its surface.

- Absorption: Adsorption is different from absorption because molecules that are being absorbed rather than adsorbed are taken inside the material. An example for that is cotton wool used for bandages. As an absorbent, cotton wool can soak up the blood from an open wound. It’s a saturation process that absorbent materials perform.

It’s easy to distinguish absorbents from adsorbents. Adsorption does not change its adsorbent visually. Odor molecules are simply “swallowed” in the process, without changing the volume, color, or any other property of the adsorbent. In contrast, after cotton wool is applied for wound treatment, its volume changes, it becomes red and wet, and feels different on the touch.

Relatable example? Pollution masks would be an example of adsorption from our daily lives. Masks are made of two or more layers of fabric, and between the layers, there is activated carbon either in the form of granules or a filter sheet. The activated carbon element is the adsorbent, while the dust and smoke particles are adsorbates.

The Anatomy of Activated Carbon: Why It Works

So, what is the adsorbent material and how is it manufactured to be so effective?

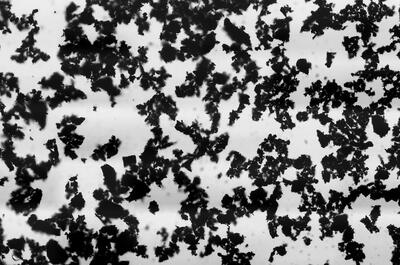

Activated carbon is essentially charcoal treated with oxygen. This manufacturing process is what unlocks its purifying “superpowers.” When carbon is subjected to oxygen, the chemical reaction opens up a many many tiny pores between the carbon atoms. Special manufacturing techniques are used to create highly-porous crystals of activated charcoals that can “adsorb” organic particles such as odors, tastes, or colors. The massive internal surface area created by these pores allows the carbon granules to attract and trap microscopic contaminants.

How Carbon Filtering Works? The surface of an activated charcoal piece has countless sites for bonding. When certain particles hover around the carbon surface, they attach to it and stay there.

What It Traps (Adsorbates): Activated charcoal is superior in trapping volatile organic compounds (such as paint, varnishes, adhesives, air fresheners, etc.), and it will only remove certain impurities circulating in the air; it’s not affecting all particles. Specifically, activated carbon can filter odors, hydrocarbons, and oil vapors from the air.

Carbon also has other superpowers, which might not be very relevant for cannabis growers. But, important, they can also be utilized to catch radon in the air, a naturally-occurring radioactive gas associated with causing lung cancer.

Practical Use and Longevity

Carbon filters are available in solid carbon, impregnated foam materials, powder, and cloth. The purification qualities of active carbon have found a wide range of use, from utilization in processing facilities to coffee machines, air conditioning units, aquariums, and essential exhaust fans that filter the air of unwanted odors.

For cannabis cultivation, the filters must be paired with an exhaust fan to pull air through the carbon bed. The key to efficiency is ensuring the contaminated air remains in contact with the carbon for a sufficient period—this is often why matching your filter’s CFM (Cubic Feet per Minute) rating to your fan is critical.

Filter Maintenance: Filters do need to be changed regularly, every few months or so, depending on the type of filter, the size of the cannabis grow room, or the plants that are being grown. Once the carbon’s bonding sites are saturated with contaminant molecules, the filter is considered ‘spent’ and odor control will fail. The primary indicators for replacement are:

- Odor Return: You begin to smell the distinctive cannabis aroma.

- Time: Most commercial filters last between 9–18 months under typical usage conditions.

Conclusion: Don't Forget to Check

Activated carbon is a powerful, yet simple, scientific solution that makes indoor cannabis cultivation possible. It’s the silent hero of the grow room.

When was the last time you changed your carbon filter?

Also read on Soft Secrets:

- All About Cannabis Smell

- Do’s and Don’ts: Masking the Odor from Your Cannabis Garden

- 10 Reasons Why You Should Consider Using Grow Tents

Last updated December 17, 2025